Differential pressure (DP) measurement has long been used in tank and other vessel level measurement. Level is calculated by taking the difference in pressure divided by the specific gravity of the liquid. I caught up with Emerson’s Anshuman Prasad, a member of the Rosemount pressure measurement team.

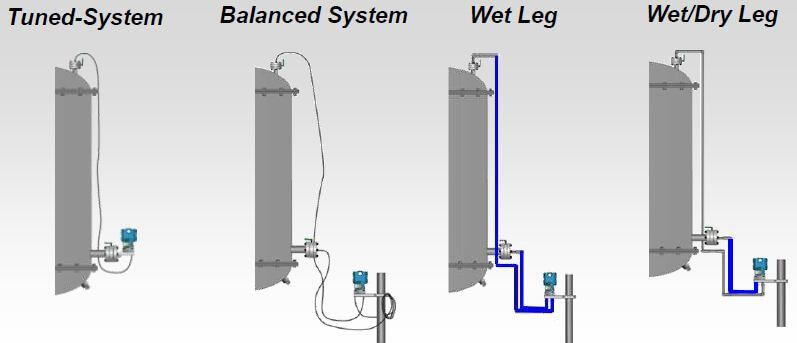

He described four traditional ways of measuring the differential pressure for level applications: wet leg, wet/dry leg, tuned system, and balanced system. Wet leg/dry legs were historically used to connect the transmitter to the vessel’s pressure flanges. Typically, this is a high-maintenance connection system and has issues with evaporation (for wet legs) and condensation (for dry legs), which contribute to inaccurate pressure measurements.

He described four traditional ways of measuring the differential pressure for level applications: wet leg, wet/dry leg, tuned system, and balanced system. Wet leg/dry legs were historically used to connect the transmitter to the vessel’s pressure flanges. Typically, this is a high-maintenance connection system and has issues with evaporation (for wet legs) and condensation (for dry legs), which contribute to inaccurate pressure measurements.

In a wet leg arrangement, the capillary tubes on both sides leading to the DP transmitter are filled with liquid.

Before describing the balanced system and tuned system, it will help to understand the temperature effect associated with capillary systems. Temperature effect has two components–seal temperature effect and head temperature effect. Seal temperature effect is caused by the backpressure generated on the sensing diaphragm when the ambient temperature changes. This causes an expansion / contraction of the fill fluid in the capillary. Head temperature effect is caused by changes in the weight of the capillary fill fluid due to density variation with varying ambient temperatures exerting backpressure on the sensing diaphragm.

In a balanced system, capillaries are the same length on both the high-pressure side and low-pressure side. Traditionally, it was believed that the same length capillary would offset the temperature effect in the capillaries. However, it only offsets the seal temperature effect and still leaves behind the head temperature effect. That gave way to tuned systems where the high side is direct mounted and low side uses a capillary.

Tuned systems use the asymmetry of the system to balance seal temperature effects with head temperature effects. It takes advantage of the fact that the two temperature effects act against each other for a given change in ambient temperature. However, errors due to capillaries are not eliminated and the response time of the system is still slow due to capillaries.

Anshuman described a new product, Rosemount 3015S Electronic Remote Sensors (ERS), which solves these issues. Two 3051S pressure transmitter are mounted on the high and low side of the tank avoiding the need for capillary tubing. The pressure sensors are linked together with an electrical cable and synchronized to create a single 3051S ERS system, calculating the differential pressure electronically.

Anshuman described a new product, Rosemount 3015S Electronic Remote Sensors (ERS), which solves these issues. Two 3051S pressure transmitter are mounted on the high and low side of the tank avoiding the need for capillary tubing. The pressure sensors are linked together with an electrical cable and synchronized to create a single 3051S ERS system, calculating the differential pressure electronically.

The speed of response is no longer limited by capillary tubing since this tubing is no longer required. The issues associated with temperature correction are also eliminated. This ERS technology also reduces the inaccuracies associated with evaporation and condensation as well as the maintenance that was required on the capillary and impulse tubing.

Communicating electronically instead of through capillary tubing also provides a method for difficult measurements including tall distillation columns, storage tanks, pulping vessels, and fermenters. And where cold weather is present, the need for heat tracing on the impulse lines is eliminated.

Anshuman noted that these HART-based devices provide scaling to convert DP into level, volume, and mass measurements and given that it’s a multivariable device, up to 4 variables can be extracted as HART signals using a THUM adapter or a HART splitter (e.g. a 333 TRILOOP).

He shared an example of a brine level measurement application, which had a wet leg installation. Salt crystals would form and plug the impulse lines. This required a complex water injection system to periodically purge the lines and cause the evaporator unit to be taken offline.

By replacing the wet leg installation with the ERS arrangement, the process manufacturer eliminated the line plugging and provided a clearer, more accurate picture of the brine level for the operators.

Another installation at a chemical facility uses ERS to eliminate the daily swings in level (in a buffer tank where level is typically fixed) reading due to change in ambient temperature within the day.

Like in so many other areas of our lives, the replacement of traditional methods with digital communications eliminates many of the workarounds we needed to develop. In this case, the installation gets easier, the measurement performance improves, and the operators have access to more accurate information.