Flexibility to meet changing customer demand benefits many manufacturers. This is especially true in the power industry as Emerson’s Douglas Morris explains.

With the growth of renewable power, generators are working to improve the flexibility of their thermal power units to help smooth the variability of power supply from wind and solar. Producers must be able to quickly respond to changing net generation conditions. Dealing with the needs of power distribution falls under the catchall category of ancillary services.

The New York Independent System Operator (ISO) does a good job defining ancillary services: “Services necessary to support the transmission of capacity and energy from generation resources to consumers, while maintaining the reliable operation of New York’s transmission system.”

These services have been around for a long time, but are more important in today’s operating environment because of the variable nature of renewables. Just by its nature, renewable generation does not sync with actual demand/load.

Forecasting the fluctuating daily power production of renewables places additional pressure on utilities with mixed generation assets. As a result, thermal plants are cycled to match load with demand.

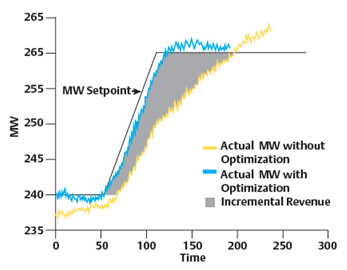

Having the agility to quickly ramp these thermal units without exceeding equipment inlet temperatures provides access to ancillary services and additional revenue opportunities. This is accomplished through boiler optimization, which provides greater megawatt-per-minute levels as well as accurate and stable steam temperature control. Optimization may include:

- Calculating variable ramp rates for optimized maneuverability and reduced temperature overshoots

- Coordinating boiler and turbine operations to manage megawatts and throttle pressure

- Synchronizing various pass dampers, burner tilts, and attemporation valves to optimize steam temperature

The bottom line is that the costs associated with this optimization are minimal compared to the loss of ancillary services which can provide thousands of dollars of additional daily revenue.