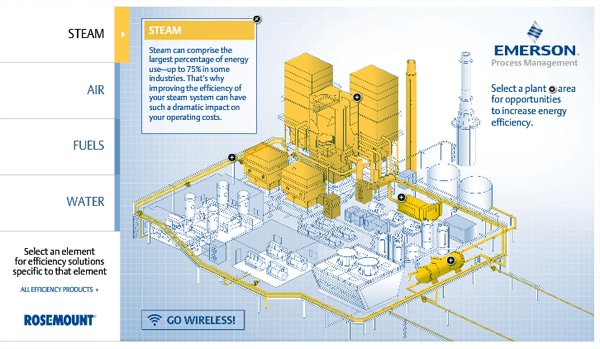

Managing the consumption of energy in a large, industrial plant can be a daunting challenge. There are systems for steam, air, fuels, and water and often these don’t have the measurements needed to see the trends in consumption and waste.

The team responsible for the Rosemount measurement products has developed a virtual tour to identify areas to measure to find efficiency opportunities. The Energy Management Solutions virtual tour highlights the opportunities in each of the plant systems.

For example, in the steam area, process units include boilers, furnaces & fired heaters, distribution piping, turbines, compressors and heat exchanges, each have important measurements that can help identify areas for efficiency gains. For the boiler, measurements include fuel input, combustion air input, steam flow out, boiler drum level, feedwater flow, and flue gas flow.

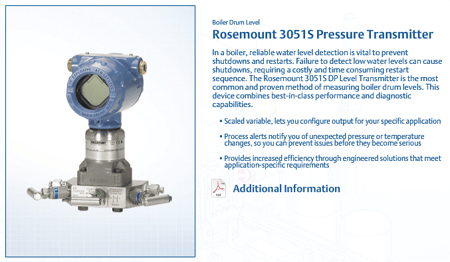

For each of these measurements, such as the boiler drum level, a suggested technology for the measurement is provided. In this example, the Rosemount 3051S DP level transmitter is a common and proven technology for drum level measurement.

For each of these measurements, such as the boiler drum level, a suggested technology for the measurement is provided. In this example, the Rosemount 3051S DP level transmitter is a common and proven technology for drum level measurement.

The additional information link goes to an interactive PDF file, which describes how this technology can impact productivity, quality, energy efficiency, and safety.

For existing plants, adding measurements can be difficult if the cabling infrastructure is not already in place with sufficient spare capacity. Wireless options are available for different measurements for temperature, flow, pressure, level, and acoustic for the steam traps.

If reducing your energy costs and increasing the efficiency of your process is part of your business objectives, take a visit around the virtual tour for the measurements that can help accomplish these objectives.

A whitepaper, Measuring for Energy Management is also available to highlight improvement opportunities.

You can connect and interact with other measurement professionals in the Analytical, Flow, Level, Pressure, Tank Gauging, and Temperature tracks of the Emerson Exchange 365 community.