We grow ever closer to next week’s Emerson Exchange Conference in Orlando and I hope we’ll have the chance to connect if you’ll be joining us. Many of the subject matter experts featured in the posts here on the blog will be there to share their experiences and best practices. And, your peers at other companies will be sharing their experiences.

Pete Sharpe

Director, Global Industry Solutions, Refining & Chemical

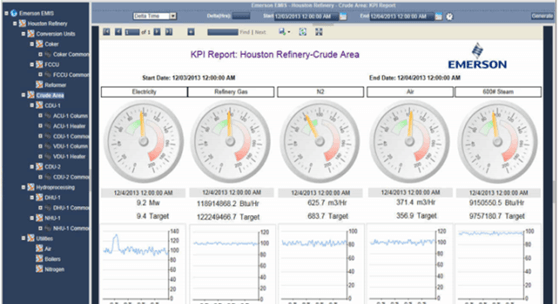

Visualizations from this application are the foundation for prioritizing energy saving projects, tracking improvements over time and taking immediate action on over-consumption events. Pete shared with me that Energy Advisor adds dashboards and advanced prediction features based on 1st principle models in addition to the standard reports available from RtTech.

Some of the visualizations include real-time energy consumption, notifications of over-consumption, overconsumption root cause analysis, and energy expense. These visualizations and analyses are available to plant staff through a web browser-based interface.

If you’ll be joining us in Orlando, make sure to catch up with Pete. In addition to finding him showing the Energy Advisor in the Industrial Energy Solutions area of the exhibit hall, he’ll be co-presenting in a workshop:

3-1891 – Valero’s Optimizer Blends Gasoline Directly to Ships

When Valero’s Pembroke refinery set out a few years ago to upgrade their aging DCS system, the vision was to not just replace in-kind. Valero’s strategy was to take advantage of new technology to optimally blend certified gasoline directly to a ship, automatically, closed-loop. In February 2014, that vision was accomplished.

You can connect and interact with other energy management professionals in the Industrial Energy track of the Emerson Exchange 365 community.