We all appreciate the diagnostics in our cars that provide early warning to get a problem fixed before a breakdown occurs. We’ve chronicled how rotating machinery diagnostics, such as PeakVue Analysis diagnostics, can provide early warning to avoid unplanned shutdowns.

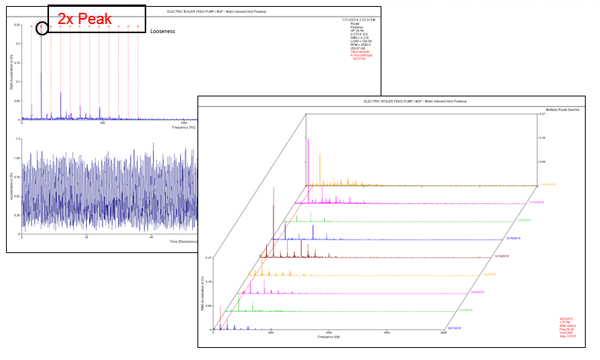

Emerson’s Jacob Swafford shared several PeakVue examples with me. A North American cogeneration power company was alerted to a high 2x peak with harmonics on a boiler feed pump motor’s inboard bearing. As this peak level increased, a machinery vibration analyst identified the problem as looseness in the bearing housing causing the bearing case to turn with the motor shaft.The repair could be scheduled instead of worsening to the point of failure and causing a loss of electrical power for their customers.

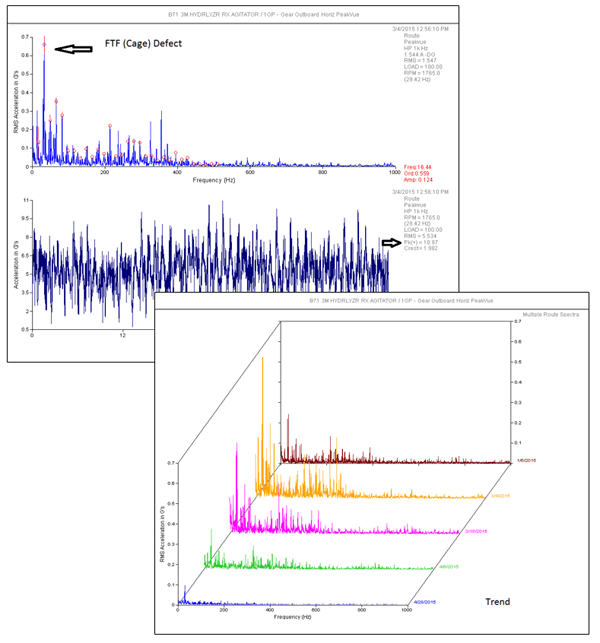

A second example Jacob shared was at a chemical manufacturing plant. An increase in vibration on a gearbox shaft outboard bearing was flagged for the watch list and data analysis was increased in frequency to once every other week. This gearbox was on a critical agitator that runs in a batch process.

The PeakVue Analysis diagnostic helped to identify a fundamental train frequency (FTF or cage frequency) defect. The amplitudes of this defect actually decreased as the Machinery Performance and Condition Monitoring Services team continued to monitor the situation, which is a good indicator of a bearing in its final stages of life.

The batch ran over the course of months so the machinery monitoring and analysis team was able to closely track the bearing to make sure it would last through the end of batch where a replacement could be planned and scheduled.

We’ll share some more stories in the coming months. Until then, you can connect and interact with other maintenance and reliability experts in the Reliability & Maintenance group in the Emerson Exchange 365 community.