Kurtis Jensen

Marketing Manager

Many plants have manual valves because it is too cost prohibitive or difficult to automate from an installation and wiring perspective. In a Valve World April edition article, Wireless valves for control, Emerson’s Kurtis Jensen highlights the advancement of wireless technology in final control elements.

Many plants have manual valves because it is too cost prohibitive or difficult to automate from an installation and wiring perspective. In a Valve World April edition article, Wireless valves for control, Emerson’s Kurtis Jensen highlights the advancement of wireless technology in final control elements.

Kurtis notes that nine of ten users have:

Common mistakes made when trying to justify a change in the current state of manual valves or automatic valves with no position feedback are underestimating the consequence of a mistake or wrong state and overestimating the cost to implement change. Kurtis writes:…acknowledged mistakes concerning valves that are in the wrong state within the past twelve months. Problems resulting from these mistakes consist of production losses, product rework or scrap, safety issues including people in undesirable situations and even worse when the local community is at risk.

Using legacy technologies limits your improvement options. Implementing wireless requires less cost, reduced time for project implementation, and fewer resources. Wireless can be easily implemented into your existing control system infrastructure with no, or minimal disruption…

Wireless provides a solution to automate valves as well as providing awareness of manual valve position. Both methods provide confirmation that the valve position is at its required set point.

Feedback is important to avoid conditions such as something stuck in the line, loss of pneumatic air pressure, or valve alignment issues. Rather than replacing the valves, Kurtis suggests to add wireless position monitoring to the valve. How?

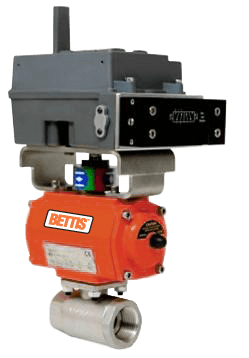

Manual valves can be converted to automated valves simply by removing the handle, adding a pneumatic actuator, and installing a wireless valve automation solution…

A wireless controller uses the same actuator and valve technologies so only the instrumentation is replaced or added. Wireless automated valves are the best replacement for valves that are currently actuated by a human.

The wireless approach avoids many installation costs including wires, cabling, junction boxes, design and drafting labor, control system interconnections, installation, and project management.

Kurtis recommends that you start small and gain experience from an installation.

Avoid solutions where valve position feedback is not included and avoid those solutions using multiple vendors. Go for a walk around your facility and look for opportunities to remove headaches and look for potential reliability improvements. Initiate test cases and start building experience levels. Begin mastering the digital intelligence possible with process control while reducing complexity for operations and maintenance.

You can connect and interact with other wireless and valve professionals in the Wireless and Valves tracks in the Emerson Exchange 365 community.