While it is well recognized that too large of a controller gain can cause excessive oscillation, not understood or addressed is the creation of nearly undamped slow process cycling and in some cases a growing instability from too small of a controller gain. This window of allowable controller gains and an associated low reset time limit has caused most gas pressure and liquid composition, level, pH, and temperature systems to continually cycle. Test results show the cause and solution for this pervasive problem of created process variability and potential risk for unsafe operation.

Greg opened noting that important column and vessel loops have slow-rolling oscillations that propagate throughout the process. His presentation sought to answer the whys, hows and whats to address these issues.

He highlighted different types of processes including near integrating, true integrating and runaway processes. Examples of near integrating processes include continuous column composition and temperature as well as vessels such as continuous bioreactors, crystallizers, evaporators, fermenters, neutralizers and reactors.

True integrating processes include level, batch column & vessel composition, pressure and temperature. Examples include batch bioreactors, crystallizers, evaporators, fermenters, neutralizers and reactors.

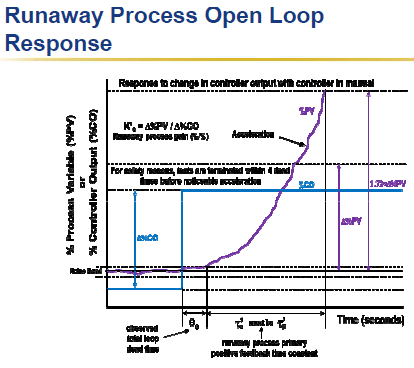

Runaway processes include polymerization reactor temperature control (highly exothermic), biological reactor cell concentration control (exponential growth phase), axial compressor speed control (precipitous drop in flow at start of surge) and strong acid and base pH control (approach to neutral point).

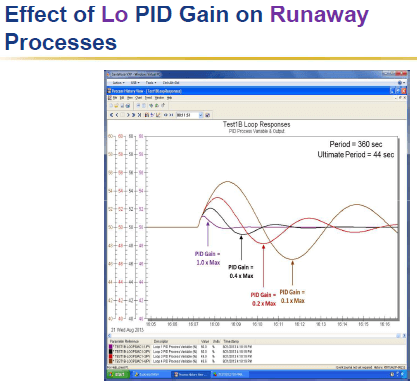

Greg noted that most think that decreasing the PID gain will improve an oscillatory effect, but for some processes, this is not right such as in a near integrating, true integrating and runaway process.

Greg showed the equations on how to attenuate the slow-rolling oscillations, allowable controller gains, inherent protection for level control, level control tuning for tight and loose control, composition and temperature control, minimizing measurement dead time and minimizing control valve and variable frequency drive (VFD) dead time.

I recorded webinars with Greg several years ago which you can google to find for a deeper dive on these process types.